Choosing the Right Tape

When a pressure-sensitive tape is bonded to a surface, a number of different processes take place. Understanding these processes will help you assure that tapes are bonded correctly and perform as expected. The polymers used to make PSA tapes can behave as both liquids and solids, depending on the circumstances. It is the tapes’ liquid behavior that becomes important initially when sticking to surfaces.

First, consider the surface to which you plan to bond the tape. It may be flat and smooth, or it may be contoured or rough. It may also have contaminants or other materials on the surface. All of these variables play a role in how well and how quickly the tape will bond.

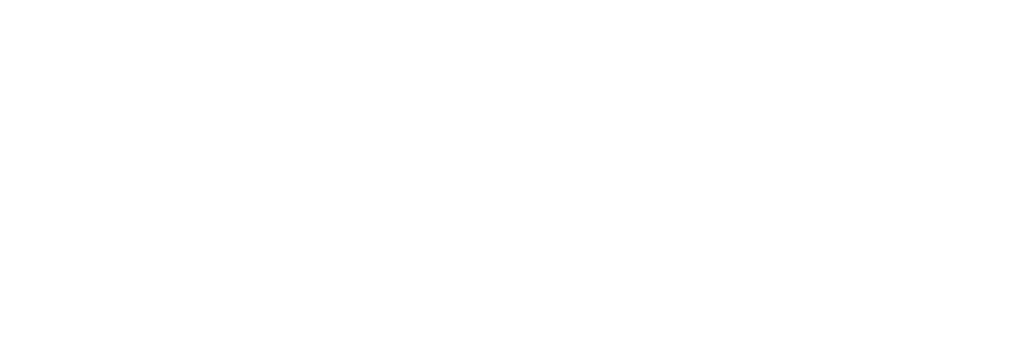

Contaminants

When a tape bonds to a surface, it forms an intimate contact between the adhesive and the surface. If there are contaminants on the bonding surface (such as dust, oil, rust etc.) then the adhesive will contact those materials, and not the surface underneath.

In this case, the amount of adhesive contacting the substrate is reduced. Accordingly, the strength of the adhesive bond is also reduced and the tape may fail in its application. Having a clean, dry surface is important to forming a good bond.

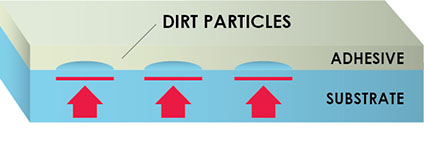

Rough Surfaces

Sometimes the surface to which the tape will stick is not smooth. For example, wood and textiles, or plastic surfaces with embossed textures. In such cases the adhesive contact will initially be strongest only at the high points of the surface. Over time, or with pressure, the adhesive will flow and start to fill out the texture of the surface. Of course, it becomes important to use tape that is thick enough to allow the adhesive to fill the depth of the texture.

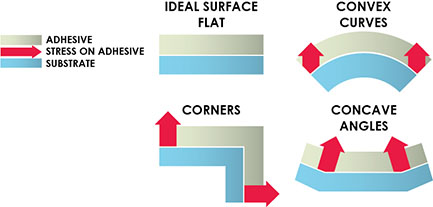

Curved Surfaces

Several factors can affect bonding when applying tape to surfaces that are not flat. The curved surface will induce forces on the edges or bend points in the tape, which can result in a de-bonding peel force that causes the tape to pull away from the surface.

In such cases it becomes important to ensure that the tape selected has a strong enough adhesion to overcome these forces. This may require selecting a much different tape than would be used to bond to the same material on a flat surface.

Temperature

It is also important to remember that the viscoelastic properties of PSA tape are temperature dependent. A tape that bonds very well at room temperature may not perform as well if you try to form a bond at much lower temperatures. Considering the application temperature is an important part of the tape selection process.

Summary

All of these points demonstrate the importance of testing a tape’s performance in your exact application, which can differ substantially from the “ideal” situation represented on a product data-sheet.